|

|

|

RIGGING HARDWARE

FORGED EYE NUTS & PAD EYES

CAUTION: NEVER EXCEED THE WORKING LOAD LIMIT.

NEVER INSERT THE POINT OF A HOOK IN AN EYEBOLT. ALWAYS USE A SHACKLE.

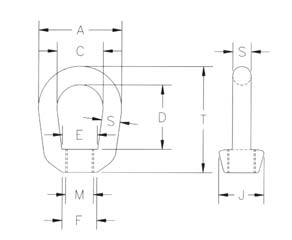

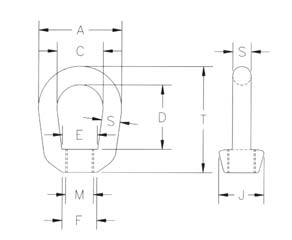

EYE NUTS

Forged steel.

Hot dipped galvanized.

Tapped with standard UNC class 2

threads after galvanizing.

WORKING

DIMENSIONS (in.)

STOCK

Std.

SIZE

LOAD

SIZE (in.)

Tap

No.

LIMIT

Weight

A

C

D

E

F

J

M

T

S

SIZE

(lbs.)

(Each lbs.)

1

0.25

1/4

520

1.25

0.75

1.06

0.66

0.50

0.69

0.25

1.69

0.09

2

0.31

3/8

1250

1.63

1.00

1.25

0.75

0.56

0.81

0.38

2.06

0.17

3A

0.38

1/2

2250

2.00

1.25

1.50

1.00

0.81

1.00

0.50

2.50

0.28

4

0.50

5/8

3600

2.50

1.50

2.00

1.19

1.00

1.31

0.63

3.19

0.60

5

0.63

3/4

5200

3.00

1.75

2.38

1.38

1.13

1.50

0.75

3.88

1.00

6

0.75

7/8

7200

3.50

2.00

2.63

1.63

1.31

1.88

0.88

4.31

1.65

7

0.88

1

10000

4.00

2.25

3.06

1.88

1.56

2.13

1.00

5.00

2.69

8

1.00

1 1/4

15500

4.50

2.50

3.50

1.94

1.88

2.38

1.25

5.75

3.87

9

1.13

1 3/8

18500

5.00

2.75

3.75

2.00

2.00

2.56

1.38

6.25

5.00

10

1.25

1 1/2

22500

5.63

3.13

4.00

2.38

2.25

3.00

1.50

6.75

6.78

11

1.50

2

40000

7.00

4.00

6.25

4.00

3.38

4.00

2.00

10.00

14.60

Ultimate Load is 5 times the Working load Limit. Rating based on standard tap size.

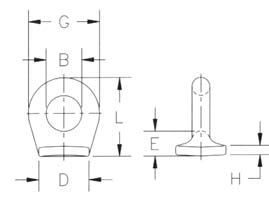

PAD EYES

Forged steel.

Forged from 1035 carbon steel.

Excellent welding qualities.

Widely used on farm machinery, trucks, steel hulled marine vessels and material handling equipment.

DIMENSIONS (in.)

WEIGHT

SIZE

PER 100

No.

B

C

D

E

G

H

L

(lbs.)

*0

2.80

0.25

0.19

0.63

0.31

0.63

0.09

0.75

*1

6.50

0.38

0.25

0.88

0.41

0.88

0.13

1.03

*1 1/2

10.40

0.63

0.25

1.00

0.44

1.13

0.16

1.31

2

21.10

0.75

0.38

1.06

0.50

1.50

0.19

1.63

4

52.20

1.00

0.56

1.44

0.78

2.13

0.22

2.34

5

82.50

1.25

0.69

1.75

0.81

2.63

0.25

2.75

*Meets the requirements of Military Specification MS 51930A.

104