|

|

|

WIRE ROPE

INSTALLATION, OPERATION AND

MAINTENANCE RECOMMENDATIONS

As a rope is run through a groove, both become smaller. A

used goove can be too small for a new rope; thus acceler

ating rope wear. A compromise between rope life and

machining frequency must be made.

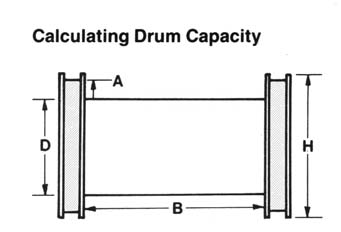

The lenth of rope that caan be wound on a drum or reel

may be calculated as follows. L= lenth of rope in feet. All

other dimensions are in inches.

L = (A + D) x A x B x K

K=Constant obtained by dividing .2618 by the square of

Grooves should have an arc of contact with the wire rope

the actual rope diameter.

between 135 and 150 degrees. They should be tapered to

permit the rope to enter and leave the groove smoothly.

A = H D Desired clearance, in inches.

Field inspection groove guages are made to the nominal

2

diameter of the rope plus 1/2 of the allowable rope oversize

tolerance. When the field inspection guage fits perfectly,

B = Traverse in inches.

the groove is at the minimum permissible contour.

D = Barrel Diameter in inches.

H = Flange Diameter in inches.

L = Rope length in feet.

Values of K

Rope

Rope

K

K

Dia.

Dia.

1/4"

3.29

1 1/2"

0.107

5/16"

2.21

1 5/8"

0.0886

3/8"

1.58

1 3/4"

0.077

7/16"

1.19

1 7/8"

0.0675

1/2"

0.925

2"

0.0597

9/16"

0.741

2 1/8"

0.0532

5/8"

0.607

2 1/4"

0.0476

3/4"

0.428

2 3/8"

0.0421

7/8"

0.308

2 1/2"

0.038

1"

0.239

2 5/8"

0.0345

1 1/8"

0.191

2 3/4"

0.0314

1 1/4"

0.152

2 7/8"

0.0287

1 3/8"

0.127

3"

0.0264

18