|

|

Installation, Operation and Maintenance Recommendations

|

Next: (continued)

|

|

WIRE ROPE

INSTALLATION, OPERATION AND

MAINTENANCE RECOMMENDATIONS

On installations where the rope

Crane ropes will fatigue at an equalizer sheave. Careful

passes over a sheave onto the

inspection is required to identify fatigue points.

drum, the maximum fleet angle

Hoist ropes will frequently fail from vibration fatigue at

(angle between the center line of

sockets,clips and dead end points.

the sheave and the rope) should be

not more than 1 1/2 degrees for a

On most installations, wear and fatigue are more severe

smooth faced drum and 2 degrees

on one half of the rope than the other. Changing a rope

for a grooved drum. A 1 1/2 degree

end for end more evenly distributes wear and fatigue from

fleet angle is equivalent to 38 feet

repeated bending and vibration.

of lead for each foot of rope travel

on either side of the center line of

Lubrication

the sheave. Smaller fleet angles

Factory lubrication is not always sufficient to last the useful

may result in the rope piling up on

life of wire rope. Periodic field lubrication may be required

the durm. Larger fleet angles may

to minimize friction and provide corrosion protection.

cause excessive wear from rubbing

Important guides for field lubrication.

against the flanges of the sheave

Ropes should be inspected frequently to determine the

as well as excessive crushing and

need for lubrication.

abrasion of the rope on the drum.

Clean the rope thoroughly with a wire brush, scraper or

compressed air to remove foreign material and old lubri

cant from the valleys between the strands and the spaces

between the outer wires.

The lubricant should be applied at a point where the

Break In

rope is being bent in order to promote penetration within

A few trips through the working cycle at slow speed and

the strands. It may be applied by pouring, dripping or

light load will set the strands firmly in place for smooth,

brushing.

efficient operation.

On applications using a wedge socket, such as drag and

Used motor oil is not recommended as a wire rope lubri

hoist ropes, it is also a good idea to cut off a short section

cant.

of rope to allow twist to run out and to equalize the

strands.

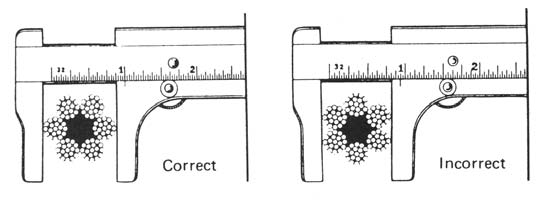

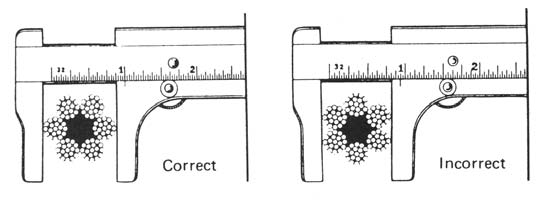

Measuring Wire Rope

Operation

Skillfull operation is important to wire rope performance.

Rapid acceleration, shock loading and excessive vibration

can cause premature rope failure. Smooth, steady appli

cation of power by the equipment operator can add signifi

cantly to wire rope service life.

Shifting Wear Points

Some sections of most wire ropes get more wear than oth

ers. A regular inspection program will identify points of

The diameter if a wire rope is the diameter of the smallest

wear and lead to wear shift practices that will extend wire

circle which will enclose all the strands. Measurements

rope life.

should be made to the outer wires.

In many commom situations, cutting off short lengths of

the rope will redistribute the points of maximum wear:

Rope on a drum with two or more layers will wear at the

point where the rope starts each successive layer.

16