|

|

Working Load Limits

|

End of Section

|

|

WORKING LOAD LIMITS

FURTHER EXPLANATIONS AND CAUTIONS IF LIFTING

ANGLES ARE INVOLVED

Numerical values published for Breaking Strength and

fering lifting angles; angular loads on shackles or eyebolts

Working Load Limit in the catalog are very specific in one

alter Working Load Limits of the equipment used.

point: They refer to straight, inline pull or force and are

obtained under laboratory conditions.

All these and other factors influencing the Working Load

Limit must be taken into account when systems are

There are, however, many applications where a straight

designed and used.

line pull is not possible or even desirable. When a tackle

block system is reeved, wire rope may be bent over many

The following is an example intended to demonstrate the

sheaves; multiple leg wire rope or chain slings involve dif

effects of angles on the Working Load limit.

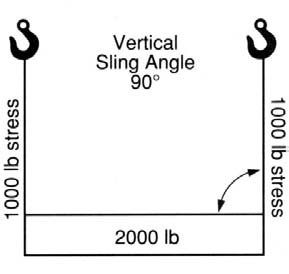

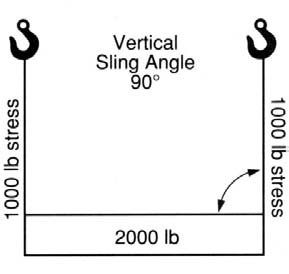

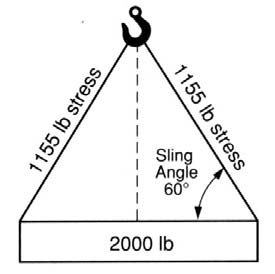

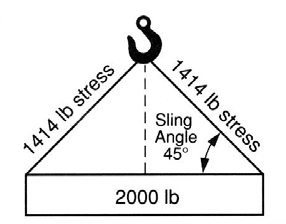

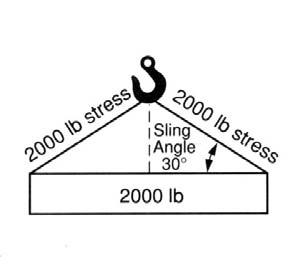

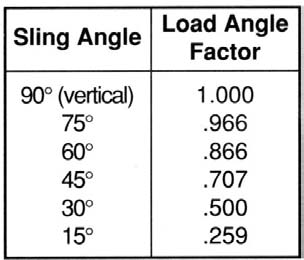

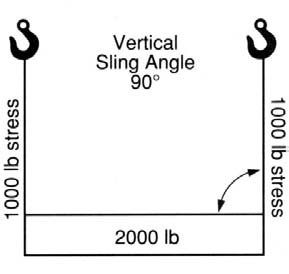

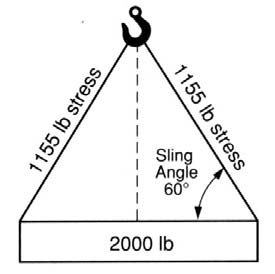

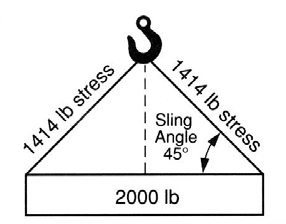

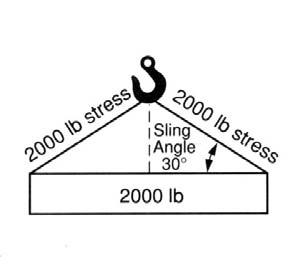

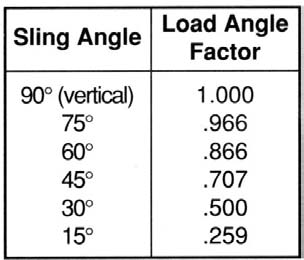

Effect of Angles on Sling Capacities

The rated capacity of a multiple leg sling is directly affect

Example:

ed by the angle of the sling leg with the load. As this

A multiple leg sling with a

angle decreases, the stress on each leg increases with

rated capacity of 2000 lb. will

the same load. If the sling angle is known, the capacity

have a reduced capacity of

can be readily determined by multiplying the sling's verti

1000 lb. and (2000 x .500)

cal capacity by the appropriate load angle factor from the

when sling legs are at an

table at right.

angle of 30 with the load.

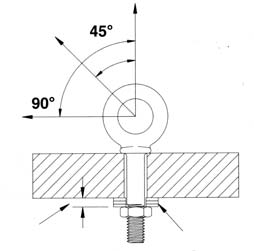

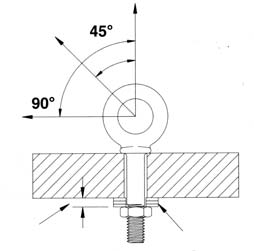

EYEBOLTS

If a load is applied at an angle, only shoulder nut eyebolts

must be used. The Working Load Limits as shown in the

Angular loads on shoulder nut eyebolts reduce the

tables on page 102 103 (drop forged, hot galvanized) of

Working Load Limit.

this catalog refer to straight line pull only.

The following table shows reduced Working Load Limit for hot galvanized shoulder nut eyebolts using 45 and 90 angles

as an example.

WORKING LOAD LIMITS POUNDS

Hot Galvanized

Shank

Diameter

Straight

45

90

1/4

500

150

125

5/16

800

240

200

3/8

1200

360

300

1/2

2200

660

550

5/8

3500

1050

875

3/4

5200

1560

1300

8